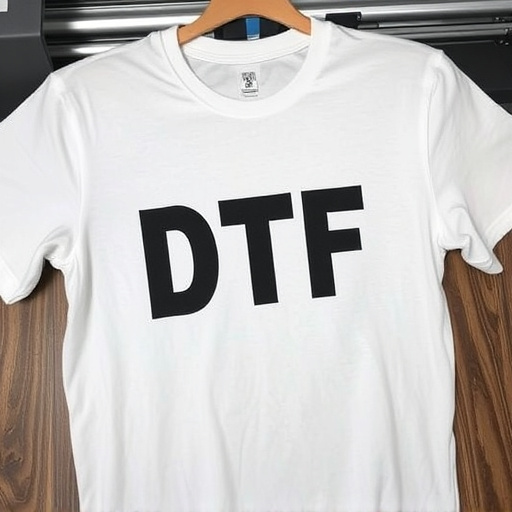

The DTF (Direct to Fabric) Heat Press is a game-changer in fabric printing, offering vibrant colors and intricate details using digital files (DTF). This technology bypasses traditional methods by directly applying ink to fabric, resulting in high-quality prints at competitive prices. Ideal for both personal projects and large-scale production, DTF Heat Press simplifies the process with user-friendly design and clear instructions. To achieve best results, start with high-resolution digital designs (300 DPI or better), carefully check for design flaws, and use appropriate transfer film and heat press settings calibrated for your material.

“Unleash the power of vibrant colors and intricate details with DTF (Direct-to-Fabric) Heat Press technology. This innovative printing method is revolutionizing the industry by offering exceptional color saturation and fine line reproduction. In this article, we’ll explore how DTF Heat Press excels in producing stunning visuals on a variety of fabrics. From understanding its underlying technology to mastering best practices for optimal results, get ready to elevate your design game with DTF Heat Press.”

- Understanding DTF Heat Press Technology

- Benefits of DTF for Vibrant Color and Detail

- Best Practices for Achieving Optimal Results

Understanding DTF Heat Press Technology

The DTF (Direct to Fabric) Heat Press is a cutting-edge technology that has revolutionized the printing industry. It’s a process that allows for the application of designs directly onto fabrics with vibrant colors and intricate details. Unlike traditional methods, this modern technique eliminates the need for screens or plates, making it an efficient and cost-effective solution.

Understanding DTF Heat Press involves grasping how it prepares and prints dtf files. The process begins with uploading your own gang sheet, a digital design file, which is then meticulously prepared for printing. This preparation ensures that the final print will be of the highest quality, showcasing every detail from bold graphics to fine lines. With the right settings, users can achieve remarkable results, making DTF Heat Press a go-to choice for those seeking exceptional fabric printing capabilities.

Benefits of DTF for Vibrant Color and Detail

The DTF (Direct to Fabric) Heat Press is a game-changer for printing vibrant colors and intricate details on a variety of materials. One of its key benefits is its ability to produce stunningly rich and accurate colors, making it ideal for brands looking to create visually appealing designs. This technology surpasses traditional printing methods by directly applying ink to the fabric, eliminating the need for middleman layers. As a result, DTF offers a cost-effective solution without compromising on quality or detail.

Additionally, the DTF Heat Press simplifies the application process, allowing users to easily print on various fabrics with precise precision. Its versatility makes it suitable for both small-scale personal projects and large-scale production runs. With online ordering platforms making the procurement process seamless, businesses can efficiently manage their printing needs. Moreover, clear application instructions ensure that even beginners can achieve professional results, further enhancing the accessibility of DTF technology.

Best Practices for Achieving Optimal Results

To achieve optimal results with a DTF Heat Press, best practices include preparing high-resolution digital designs and ensuring proper alignment. Start by using vector graphics or high-quality raster images with a minimum resolution of 300 DPI, as this ensures sharp details when transferred to various materials. Before printing, carefully check for any design imperfections, such as text that’s too small or intricate lines that might be lost in the final product.

Additionally, selecting the right DTF transfer film and heat press settings is crucial. Use a film specifically designed for your press to guarantee optimal adhesion and color vibrancy. Calibrate your heat press according to the material you’re working with—whether it’s clothing, mugs, or other items—and adjust the temperature and pressing time accordingly. Following these guidelines will help you produce stunning, detailed DTF prints every time, leveraging the capabilities of your heat press for exceptional results.

The DTF Heat Press technology has proven to be a game-changer in achieving vibrant colors and fine detail on various materials. By understanding its capabilities and implementing best practices, creators can unlock the full potential of this innovative process. Whether you’re a professional or an enthusiast, mastering the art of DTF Heat Press will enable you to produce stunning, high-quality designs that capture the essence of your creativity.