The DTF Heat Press is a revolutionary technology for custom fabric printing, offering fast, high-quality results with minimal setup. It uses precision heating, transfer films, and specialized powders to eliminate complex machinery, enabling users to easily create unique designs on various fabrics, ideal for vibrant patterns or simple text on items like hoodies and t-shirts.

Discover the power of a DTF (Direct-to-Fabric) heat press, a revolutionary technology transforming the custom printing industry. This advanced system seamlessly fuses transfer films and powders onto fabrics with precise heat and pressure, delivering high-quality, vibrant prints. In this guide, we’ll explore the inner workings of a DTF heat press, from understanding its cutting-edge technology to mastering the art of preparing transfer film and powder for flawless printing results.

- Understanding DTF Heat Press Technology

- Preparing Transfer Film and Powder for Printing

- The Printing Process: From Setup to Finish

Understanding DTF Heat Press Technology

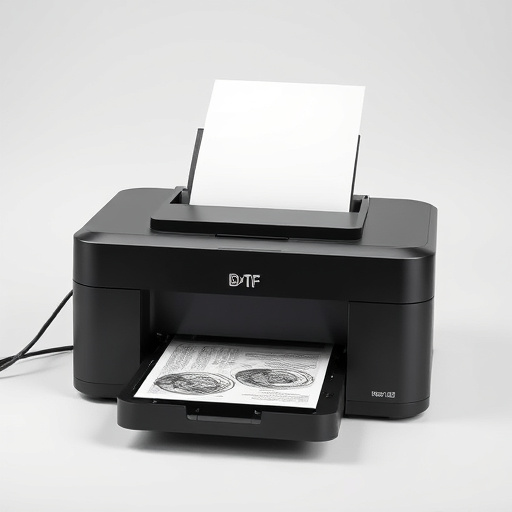

The DTF (Direct to Fabric) Heat Press is a cutting-edge technology revolutionizing the custom printing industry. It’s a game-changer for businesses and individuals looking to create unique, high-quality designs on various fabrics with ease. This innovative system combines precision heating elements, advanced transfer films, and specialized powders to achieve exceptional results. By eliminating the need for complex machinery and multiple steps, the DTF Heat Press simplifies the process of applying intricate graphics and textiles to a wide range of materials.

As a popular choice among custom dtf transfers, this technology offers a fast and efficient method for producing high-resolution prints. The best dtf printer models are designed with versatility in mind, allowing users to experiment with different fabrics, inks, and designs. Whether it’s a vibrant, intricate pattern or a simple text message, the DTF Heat Press ensures consistent quality and precise color reproduction, making it an attractive option for those seeking to bring their fabric printing ideas to life quickly and effectively.

Preparing Transfer Film and Powder for Printing

Before using a DTF (Direct-to-Film) Heat Press, it’s crucial to prepare the transfer film and powder correctly for optimal printing results. The process begins with selecting high-quality transfer films suitable for your desired substrate, whether it’s fabric, wood, or other materials. Ensure these films are compatible with your direct-to-film printer to guarantee smudge-free transfers.

Next, measure and weigh the appropriate amount of powder, typically a specialized heat-sensitive powder that reacts when exposed to heat. Properly distributing the powder on the transfer film according to the design specifications is essential. This meticulous preparation ensures precise color replication and vivid designs during the printing process, making your DTF printing for hoodies or other DTG for t-shirts projects a success.

The Printing Process: From Setup to Finish

The DTF (Direct to Fabric) Heat Press printing process begins with careful setup. The operator ensures the dtf transfers are properly aligned on the fabric, which is then positioned inside the heat press machine. Precise temperature and pressure settings are selected based on the type of fabric and desired print quality. Once ready, the heat press applies heat and pressure to transfer the design from the dtf transfer film onto the fabric. This intricate process typically takes just a few minutes.

After the printing cycle, the heat press cools down, and the finished dtf prints are carefully removed from the machine. The vibrant, long-lasting designs are now permanently infused into the fabric, showcasing precise details and rich colors. Quality control checks ensure that the dtf prints meet the desired standards before packaging for shipping or further customization.

A DTF (Direct-to-Fabric) heat press is a game-changer in the printing industry, offering a versatile and efficient method for transferring designs onto various materials. By combining transfer film and powdered pigment, this technology enables precise, vibrant prints on demand. With a well-prepared workspace and a clear understanding of the process, anyone can master the art of DTF heat pressing, unlocking endless creative possibilities for customizing apparel and accessories.