The DTF Heat Press revolutionizes custom apparel by offering a superior heat transfer method with even pressure distribution for vibrant, long-lasting prints on diverse fabrics. This technology enables precise application of ink directly to fabric through heating, resulting in exceptional clarity and color saturation. Ideal for both professionals and hobbyists, it minimizes risks of uneven heating and guarantees consistent heat penetration for intricate designs. Choosing the right DTF Heat Press involves considering press size, weight capacity, precise temperature control, fabric compatibility, and print size versatility for top-quality custom prints.

Get even pressure distribution with a quality DTF heat press and elevate your printing games. This innovative technology ensures precise and uniform heat transfer, delivering exceptional results every time. In this article, we’ll explore the fundamentals of DTF (Direct-to-Fabric) heat press technology, delve into the benefits of even pressure distribution, and guide you in choosing the perfect DTF heat press tailored to your needs.

- Understanding DTF Heat Press Technology

- Benefits of Even Pressure Distribution

- Choosing the Right DTF Heat Press for Your Needs

Understanding DTF Heat Press Technology

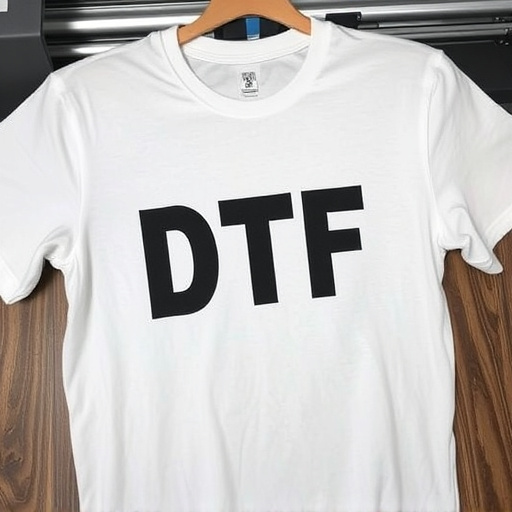

The DTF Heat Press technology is revolutionizing the custom apparel industry. It’s a game-changer when it comes to creating personalized, high-quality garments like hoodies and t-shirts. Unlike traditional heat transfer methods, DTF (Direct to Film) offers even pressure distribution, ensuring precise and vibrant prints on various fabrics.

This innovative process involves applying a thin film of ink directly onto the fabric, followed by a heating process that fuses the design. The result is a stunning, long-lasting custom DTF transfers with exceptional clarity and color saturation. Whether you’re creating direct to film personalized hoodies or any other custom apparel, the DTF Heat Press guarantees unmatched quality and detail in your designs.

Benefits of Even Pressure Distribution

Even pressure distribution is a key advantage offered by DTF (Direct-to-Fabric) Heat Press machines. This uniform pressure ensures that the heat and pressure are applied consistently across the entire print surface, resulting in high-quality transfers with precise details. With an even pressure distribution, you can achieve vibrant, long-lasting prints on various fabric types, making it ideal for professional and hobbyist use alike.

Compared to traditional methods, a DTF Heat Press with optimal pressure distribution offers several benefits. It minimizes the risk of uneven heating, which can cause shadows or missing areas in your design. Moreover, it allows for more consistent heat penetration, ensuring that the ink fully fuses with the fabric for a durable finish. This precision and consistency are particularly valuable when working with intricate or detailed designs, as they guarantee that every element of your print is accurately transferred onto the fabric.

Choosing the Right DTF Heat Press for Your Needs

Choosing the right DTF (Direct-to-Garment) Heat Press is pivotal for achieving even pressure distribution and high-quality custom t-shirt prints or DTF transfers. Key factors to consider include the press’s size, suitable for your desired print sizes, and weight capacity to handle various garments. A top-tier DTF Heat Press should offer precise temperature control and consistent heat application to ensure vibrant, indelible prints.

Additionally, think about the type of materials you’ll be working with—cotton, polyester, or a mix—as different fabrics require specific pressure and heat settings. Look for models that accommodate both custom t-shirts and DTF transfer sheets, allowing versatility in your printing projects. High-quality presses often come with advanced features like digital temperature control and automatic closing mechanisms, enhancing efficiency and precision during DTF prints.

A DTF (Direct-to-Fabric) heat press is an invaluable investment for anyone seeking optimal printing results. By ensuring even pressure distribution, these advanced machines revolutionize the garment decoration process, allowing for crisp, high-quality prints. With various models available to suit different needs, selecting the right DTF Heat Press enables professionals and enthusiasts alike to achieve consistent, outstanding outcomes, elevating their work in the competitive world of custom apparel.